CATL, a global leader in battery technology, is at the forefront of innovation in the electric vehicle (EV) and energy storage sectors. As the demand for high-performance, cost-effective batteries continues to grow, CATL’s strategies for reducing production costs and advancing solid-state battery technology are of significant interest. This article explores CATL’s plans to reduce production costs to $100/kWh, the challenges in scaling up full-solid state battery production, and the impact of fast charging on battery lifespan.

CATL’s Strategy to Reduce Production Costs to $100/kWh CATL has set an ambitious goal to reduce the production cost of its batteries to $100/kWh. This target is crucial for making electric vehicles more affordable and competitive with traditional internal combustion engine vehicles. To achieve this, CATL is focusing on several key strategies:

- Technological Innovations: CATL is investing heavily in research and development to improve battery chemistry and design. By enhancing the energy density of its batteries, CATL can reduce the amount of raw materials needed, thereby lowering costs.

- Manufacturing Improvements: The company is also optimizing its manufacturing processes to increase efficiency and reduce waste. Advanced automation and precision engineering are key components of this strategy.

- Supply Chain Optimization: CATL is working closely with its suppliers to secure raw materials at lower costs. This includes strategic partnerships and investments in mining and processing facilities.

- Economies of Scale: By expanding its production capacity, CATL aims to achieve significant economies of scale. Larger production volumes can lead to lower per-unit costs, making the $100/kWh target more achievable.

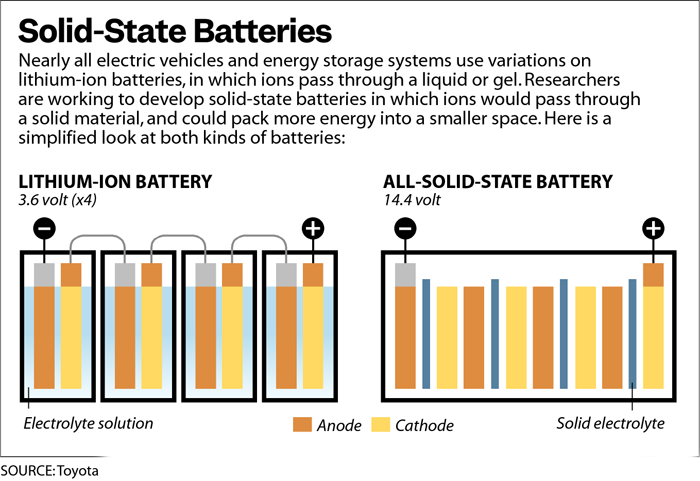

Challenges in Scaling Up Full-Solid State Battery Production While CATL is making progress in reducing costs for its current battery technologies, the development of full-solid state batteries presents a different set of challenges. Full-solid state batteries offer several advantages, including higher energy density, faster charging, and improved safety. However, transitioning from laboratory research to mass production is complex.

- Material Challenges: Solid-state electrolytes, a key component of full-solid state batteries, require precise manufacturing processes to ensure high ionic conductivity and mechanical stability. Developing cost-effective and scalable methods for producing these materials is a significant hurdle.

- Interface Stability: Ensuring stable interfaces between the solid electrolyte and the electrodes is crucial for battery performance and longevity. Any imperfections or inconsistencies can lead to reduced efficiency and potential safety issues.

- Production Complexity: The production of full-solid state batteries involves more complex manufacturing processes compared to traditional lithium-ion batteries. This complexity increases the risk of defects and inconsistencies, which can affect battery performance.

- Cost: While full-solid state batteries promise long-term cost savings, the initial investment in research, development, and production infrastructure is substantial. Balancing the high upfront costs with the potential benefits is a delicate challenge.

Impact of Fast Charging on Battery Lifespan Fast charging technology is a game-changer for electric vehicles, but it comes with trade-offs. The rapid transfer of energy into the battery can lead to increased heat generation and mechanical stress, both of which can degrade battery performance and lifespan.

- Thermal Management: Fast charging generates significant heat, which can accelerate battery degradation if not managed properly. Advanced thermal management systems are essential to maintain optimal operating temperatures.

- Electrochemical Stress: The rapid charging process can cause mechanical stress within the battery, leading to the formation of micro-cracks and other structural defects. These defects can reduce the battery’s overall lifespan.

- Battery Management Systems: Sophisticated battery management systems (BMS) are required to monitor and control the charging process. These systems can optimize charging rates and prevent overcharging, which helps to mitigate the negative impacts of fast charging.

- Material Innovations: Research into new materials and electrolytes that can withstand the rigors of fast charging is ongoing. These innovations aim to improve battery resilience and extend lifespan.

Conclusion CATL’s ambitious plans to reduce production costs and advance solid-state battery technology are driving significant progress in the battery industry. While challenges remain in scaling up full-solid state battery production and managing the impact of fast charging on battery lifespan, the potential benefits are substantial. As CATL continues to innovate and optimize its processes, the future of electric vehicles and energy storage looks increasingly promising.

Frequently Asked Questions

- How does CATL plan to achieve the $100/kWh cost target?

- CATL is focusing on technological innovations, manufacturing improvements, supply chain optimization, and economies of scale to reduce production costs.

- What are the main challenges in scaling up full-solid state battery production?

- Key challenges include material development, interface stability, production complexity, and high initial investment costs.

- How does fast charging affect battery lifespan?

- Fast charging can generate heat and mechanical stress, leading to battery degradation. Advanced thermal management and battery management systems are essential to mitigate these effects.

- What role do battery management systems play in fast charging?

- Battery management systems monitor and control the charging process to optimize rates and prevent overcharging, helping to extend battery lifespan.

- Are there any new materials being developed to improve fast charging performance?

- Yes, researchers are exploring new materials and electrolytes that can withstand the rigors of fast charging and improve battery resilience.

- How will the widespread adoption of fast charging impact the electrical grid?

- Fast charging stations place a significant load on the electrical grid, requiring infrastructure improvements and smart grid technologies to manage the increased demand.

References

- Challenges in speeding up solid-state battery development. Nature.

- Battery Industry Report 2025. StartUs Insights.

- Challenges and opportunities for high-quality battery production. Nature.

- Battery Market Outlook 2025-2030. GlobeNewswire.